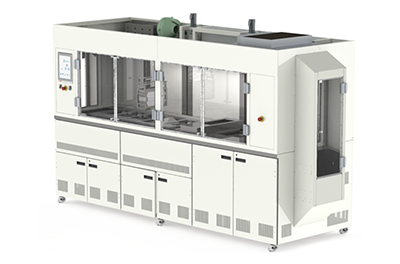

W200-SEMI

Shyre’s W200 automated wet bench ultrasonic cleaning system was developed specifically for the semiconductor industry. The W200 is a wet bench tool designed to meet the stringent requirements of the semiconductor manufacturing processes; the system provides a reliable and cost-effective solution for cleaning and preparation of wafers and other sensitive components during production.

FPI

Shyre is a leader in automatic FPI machines. FPI (Fluorescent Penetrant Inspection) is a non-destructive inspection method that is used to detect surface defects in metallic and non-metallic parts. The process is used extensively for quality control of critical castings in industries such as orthopedic medical devices and aerospace components. The process involves ultrasonic cleaning […]

SF-30 SSC – Solvent Cleaning System

Solvent retention features unique to the Shyre range: triple coil reflux cooling, vapour break, 150% freeboard, (with optional auto top-up and solvent monitoring on the larger systems) – ensure that systems are safe and comply fully with environmental and safety legislation. These design features also mean that Shyre systems can operate with low, predictable solvent […]

PC200 – Aqueous Cleaning System

Automated solutions with precision results, the PC200 provides a range of production options and adaptive for a number of configurations on request. Application: Precision Clean Configuration Processing prior to AR coating, precision/delicate optical cleaning.

US14 / US28 – Benchtop Ultrasonic Baths

Shyre Benchtop Ultrasonic Baths provides high performance tool cleaning and lens stripping applications. Designed for consistent results with digital accuracy.